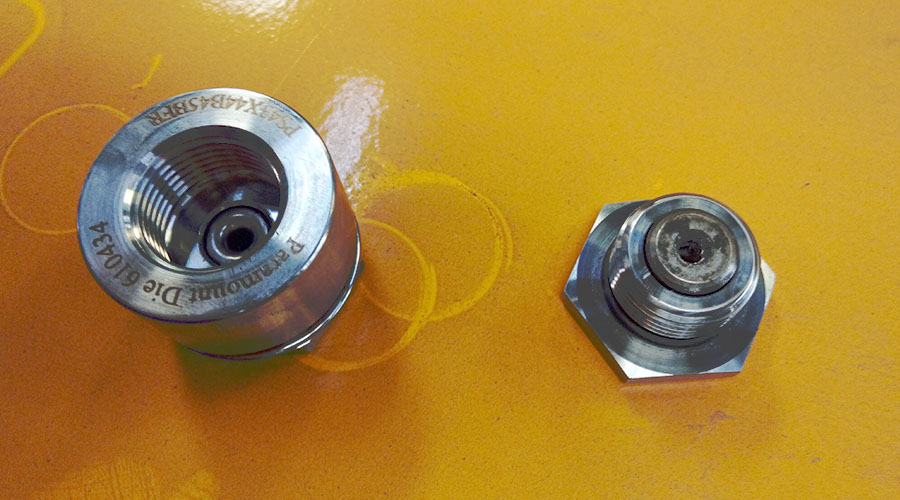

Nano-coated wire drawing dies in steel wire production: In the steel wire production process, the drawing die is a crucial tool. It directly affects product dimensional accuracy, surface quality, mechanical properties, and production efficiency.

In order to improve the company’s wire drawing machine production efficiency and product quality, we can take the following methods:

First of all, choose a diamond nano-coated wire drawing die with high processing quality. This kind of mold has the characteristics of high hardness, low friction coefficient, high smoothness, precision, and fineness, and the hole shape and dimensional accuracy are also extremely high. The quality of steel wire processed by this mold is very good.

Secondly, the linear mold pass design is adopted. When making a wire drawing die, the longitudinal section of each part is required to keep a straight line, and the junction must not be inverted or sharp. In addition, the length of the inlet area and the working area also needs to be appropriately lengthened to establish a good lubrication pressure. The sizing area must be straight and of a reasonable length to ensure the quality of the steel wire.

Third, to ensure good surface quality of the wire, it is necessary to remove the scale and select a suitable lubricating liquid or lubricating powder. This helps to reduce surface roughness and oxidation and improve the surface quality of the steel wire.

Fourth, the design of the compressor also needs to be reasonable. As for the compression rate of the company, the first and last drawings are generally adopted to select a smaller compression rate, the second drawing is to take the maximum compression rate, and then the distribution principle is stable or gradually reduced. Such a design can make the steel wire receive uniform pressure during the stretching process, thereby improving the mechanical properties of the product.

Finally, it is also very important to strengthen the cooling of the mold. We can use self-retained water cooling or forced water cooling, which is an essential cooling method for the production of high-carbon steel wire. Through effective cooling measures, the mold temperature can be reduced, the life of the mold can be extended, and the drawing effect of the steel wire can be improved.

To sum up, through the improvement and optimization of the above aspects, the efficiency and product quality of steel wire production can be effectively improved. These methods include selecting high-quality nano-coating wire drawing dies, optimizing die pass design, improving lubrication conditions, reasonably setting compressor compression ratios, strengthening die cooling, etc.

Through the comprehensive use of these methods, it can bring higher production efficiency and better product quality to the company.