How to effectively reduce the noise of the flat wire drawing machine? Everyone should know that as long as the object vibrates, it will definitely make a sound. Once this sound affects our normal rest, work, or study, then this sound is noise.

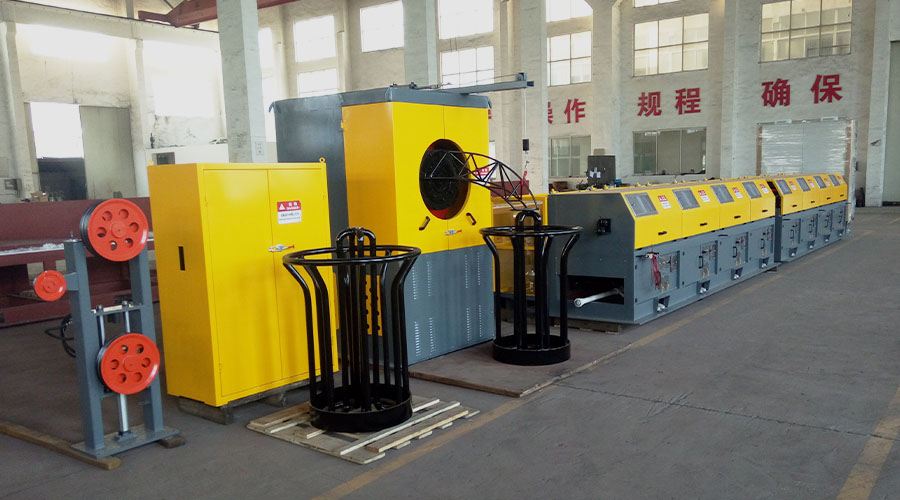

In many factories, large flat wire drawing machines make a lot of noise when they are working, which has a serious impact on the personal health of the workers who operate and work in the same workshop as the flat wire drawing machine.

Therefore, how to effectively reduce the noise of the flat wire drawing machine is an urgent problem to be solved.

According to the analysis, there are two main reasons for the serious noise of the flat wire drawing machine:

When the gears of the wire drawing machine are rotating, the meshing noise is the main source of heavy noise in the whole wire drawing machine. During the process, there will be a relatively large meshing noise.

As long as the gap between the teeth of the gear pair is adjusted to an appropriate distance, and each gear pair is guaranteed to be fully lubricated, the meshing noise can be effectively reduced.

In fact, when the casing is loose, the flat wire drawing machine will also produce serious noise. After the wire drawing is finished, as long as all the wire-receiving devices come into contact with or touch the φ3 copper wire, there will be serious noise, so changing the gasket to a polytetrafluoroethylene plate will greatly reduce the noise.

The personnel who operate the flat wire drawing machine and those working around must wear professional earplugs or anti-noise protective gear.