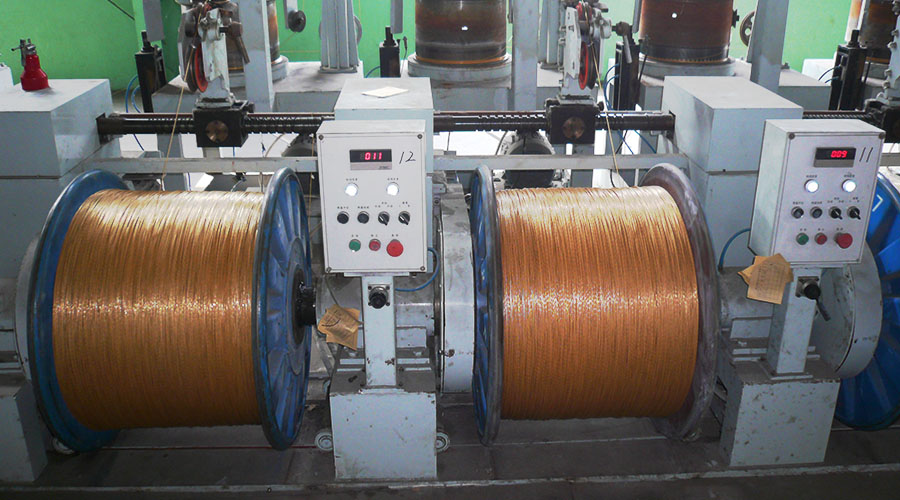

The production of copper wire drawing machines is a matter of great concern to all cable manufacturers because the quality and efficiency of wire drawing directly affect the manufacturer’s subsequent processes, and play a decisive role in the quality of cables.

The purpose of the copper wire drawing machines is to draw wires or bars produced and transported by steel manufacturers to standard parts and other metal product manufacturers through the wire drawing machine.

Make the diameter, roundness, internal metallographic structure, surface finish and straightness of the wire or rod meet the raw material processing requirements for the production of metal products such as standard parts.

Control of product outer diameter deviation

Due to the uninterrupted production of the copper wire drawing machines, the drawing speed will gradually become out of sync with the annealing, which will cause intermittent and irregular changes in the wire diameter due to the fast and slow pulling speed during wire drawing. The reasons for this phenomenon are as follows:

1. The tension on the wire storage wheel is unstable. There may be many places where air pressure is used in the production workshop, which will cause the air pressure of the air pump of the drawing machine to be high and low, which also makes the tension of the wire storage device not constant.

Since the speed of taking up the wire is constant, the pulling force on the wire drawing is also non-constant, which can cause the outer diameter deviation of the single wire to be uncontrollable.

2. The vibration of copper wire on the annealing wheel.

This causes the copper wire to be annealed in a state of looseness and tightness. The annealing current density is sometimes high and sometimes small, and the strength of the copper wire at higher speeds is relatively low.

Therefore, it is easy to cause the copper wire to spark on the annealing wheel, causing the surface of the copper wire to have uneven wire diameter due to the action of sparks.

3. Wear caused by long-term use of the main motor gearbox.

This can make the speed of the fixed speed wheel of wire drawing not match the traction speed and take-up speed, resulting in the thinning of the single wire.

Solution:

Lubricate the thread storage device well to prevent it from causing reverse friction on the thread during high-speed operation and thus thinning the thread; adjust the thread tension so that the drawing stroke is always close to the annealing wheel;

Ensure the integrity of the annealing wheel steel ring to avoid unstable annealing current due to surface defects of the steel ring.

Rematch the mold of the copper wire drawing machine according to the actual situation of the wire drawing machine: adjust according to the wire drawing principle so that the annealing wheel speed/fixed speed wheel speed = forward slip coefficient × fixed speed wheel diameter/annealing wheel diameter.

The diameters of the fixed-speed wheel and the annealing wheel are known, and the rotational speeds of the fixed-speed wheel and the annealing wheel can also be measured.

From this, the forward slip coefficient can be obtained, and the wire drawing machine can be re-molded based on the slip coefficient so that the mold can meet the requirements.

There are varying degrees of oxidation on the surface of the monofilament pulled out by the copper wire drawing machines.

This problem may occur for the following reasons:

1. The temperature of the cooling water in the sealed chamber is too high, exceeding 40°C, so the sealed chamber cannot achieve the required cooling effect on the monofilament.

As a result, the temperature of the monofilament is still very high after annealing, and it is oxidized when it encounters oxygen in the air at high temperatures.

2. The saponified liquid content of the coolant in the sealed chamber is insufficient, which will increase the friction between the monofilament and each guide wheel, thereby causing the temperature of the monofilament to rise again, causing surface oxidation of the monofilament.

3. The water pressure and volume of the cooling water in the sealed chamber are insufficient so the monofilament cannot achieve a satisfactory cooling effect.

Solution:

Always check whether the equipment for cooling circulating water is operating normally and whether the cooling effect is normal;

Add substances that can increase the concentration of saponified liquid into the sealed chamber at certain intervals, which can change the content of saponified liquid in the cooling water and ensure that the monofilament can run normally on the guide wheel;

Regularly check whether the water pressure of circulating water is normal. During production, constantly change the pressure and volume of cooling water entering the sealed chamber according to changes in water pressure.

Frequent wire breakage often occurs during the production of copper wire drawing machines.

This situation occurs mainly due to the following factors:

1. The sizing area of the wire drawing die will become larger due to normal wear during uninterrupted production。

2. Due to quality problems of various pole materials.

During the production process, quality defects occur irregularly in the rods, which causes the monofilament to be broken by various unpredictable tensions during drawing deformation. This situation occurs less often when the rod material is good.

3. Due to the instability of the annealing current during production, the current is suddenly high, and the monofilament is pulled off during the annealing process or fused by the sudden strong current.

Solution:

Before production, sufficient self-inspection of the copper rods to be produced should be carried out to promptly discover the quality defects of the copper rods.

Find corresponding countermeasures in time according to different situations, either reduce the drawing speed or remove the defective section.

During production, constantly observe whether the annealing current of the wire drawing is normal, especially when it has just started, and pay special attention to the change of annealing current.

The annealing current should be adjusted according to the change of line speed so that the annealing current slowly increases with the increase of line speed to ensure the normal operation of the equipment.

I believe that as long as we focus on controlling the above points in actual production, the quality and production efficiency of copper wire drawing products of copper wire drawing machines will be improved to varying degrees.

Only in this way can we provide a strong production guarantee for the next process production better and faster.