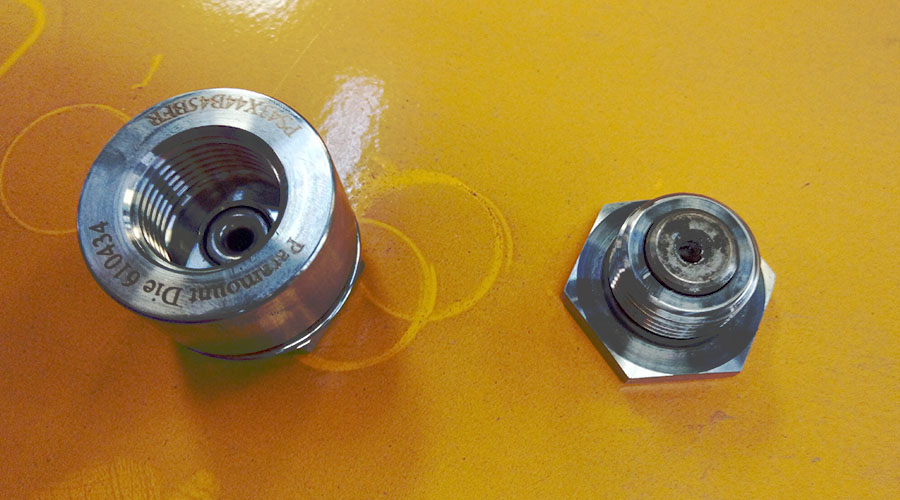

The cemented carbide wire drawing die is mainly divided into 6 work areas, and each different work area has different functions. The following is the working process of the cemented carbide wire drawing die.

- Import area: the import area is precision polished to facilitate the smooth threading of the import and the rotation of the wire drawing lubricant;

- Lubricating area: the lubricating area is highly polished to make the wire transition easily;

- Compression zone: The linear working zone can reduce the drawing resistance, change point contact to surface contact, reduce friction and mold wear, and make the deformation structure more reasonable and stable. It can be drawn smoothly when the incoming wire becomes thicker or thinner in the previous pass;

- Sizing area: The linear sizing area can guarantee the accurate diameter, smoothness, and out-of-roundness of the wire for a long time.

- Safety angle: The safety angle can ensure that the wire is pulled out without scratches, and the service life tends to be longer and longer.

- Exit area: The exit area can ensure the smooth exit of wire rods.

Manufacturing steps of cemented carbide wire drawing die:

- Die blank processing

The core of the cemented carbide wire drawing die will shrink during the sintering process.

Due to the differences in composition, pressing, and sintering process of different batch numbers, the amount of shrinkage is also quite different; the shrinkage of each part of the mold blank is different, often forming a “saddle” or “Trumpet” shape.

Although the fluctuation of the shape of the mold blank conforms to the standard of the mold blank, it far exceeds the requirement of the interference when the mold is set and set, resulting in a serious uneven prestress on the mold core during the set and set, and the service life of the mold is greatly reduced.

Therefore, the mold blank must be for cylindrical grinding, it is necessary to use a special fixture on the grinding machine and grind it with a diamond grinding wheel.

- The interference of setting

In order to obtain a certain prestress for the mold core during mounting, the diameter of the inner hole of the mold sleeve should be smaller than the outer diameter of the mold core, and the difference between the two is called interference.

The amount of interference should be determined according to the size and deviation of the core, the drawing stress and the method of inserting.

Actual interference during mold mounting. There are two types of die sets, hot pressing and cold pressing.

The cold pressing method has a small interference and a small pre-compression stress.

It is mostly used to manufacture wire drawing dies with small specifications and for drawing soft metals.

- Die sleeve processing

The mold cover is formed by turning on a lathe, and the key points of control during processing are as follows:

I) The inner diameter roughness of the mold sleeve must reach 0.80-1.6 m, which is conducive to the tight fit with the mold sleeve;

2) The inner diameter of the mold sleeve should be in one-to-one correspondence with the outer diameter of the mold blank to ensure that the interference of each mold is accurate;

3) The bottom surface of the inner hole of the mold sleeve must be parallel to the outer end of the mold, and ensure that it is perpendicular to the center line of the mold hole after assembly;

4) The ellipticity of the inner hole of the mold sleeve should be as small as possible, and should not be greater than 0.02 mm. When hot-fitting, the outer surface of the mold sleeve should be polished to ensure uniform cooling after mounting.

- Mounting process

The cold pressing method is to press the mold base into the mold sleeve with a press at room temperature. The cold pressing method requires accurate interference, and requires high dimensional accuracy of the mold core and mold sleeve. The advantage is that it does not require heating equipment, saves energy and reduces costs.