In the production process of stainless steel castings, abrasive belt polishing machine grinding can be very conveniently used for grinding planes, inner and outer circles, and complex curved surfaces.

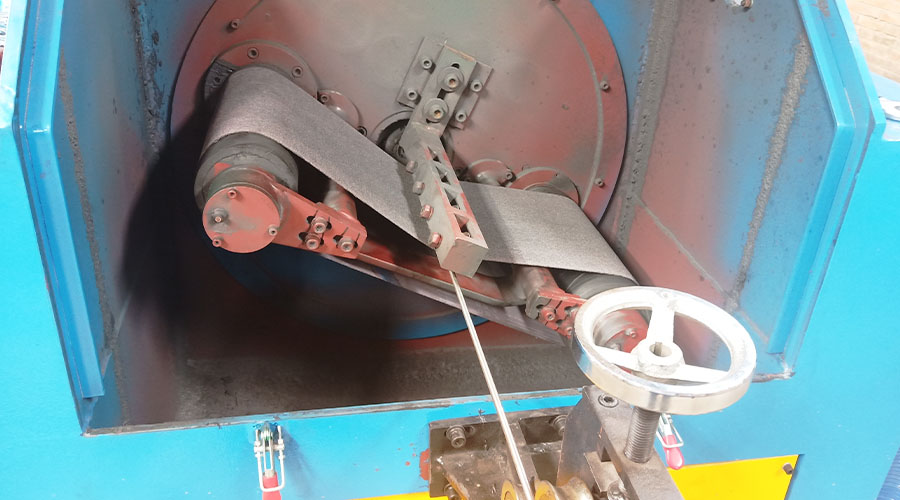

- An abrasive belt grinding head device is designed as a functional part, which can be installed on a lathe for post-turn grinding, can also be installed on a planer, and can also be designed into various special grinding machines. Utilizing this characteristic of abrasive belt grinding can easily solve some difficult-to-machine parts, such as the precision machining of super-long, super-large shafts, and plane parts.

- The base material, abrasive material, and adhesive of the abrasive belt have a wide range of choices, which can meet the needs of various purposes. The grain size, length, and width of the abrasive belt also have various specifications, and there are various forms such as rolls and rings to choose from. For the same workpiece, abrasive belt grinding can be processed by various grinding methods and process structures.

- Compared with grinding wheel grinding, abrasive belt grinding is called (cold grinding), that is, the grinding temperature is low, and the surface of the workpiece is not easy to be burnt.

- The abrasive belt grinding system has low vibration and good stability.

- The grinding speed is stable, and the abrasive belt drive wheel will not grind slower as the diameter becomes smaller than the grinding wheel does.

- The abrasive belt grinding equipment is simple. Compared with a belt grinder, a belt grinder is much simpler, mainly because the belt is light in weight and has less grinding force. The vibration is small during the grinding process, and the rigidity and strength requirements of the machine tool are far lower than those of the grinding wheel grinder.

- The abrasive belt polishing machine is easy to operate and requires less auxiliary time. Whether it is manual or motorized abrasive belt grinding, its operation is very simple. From changing and adjusting the abrasive belt to clamping the workpiece to be processed, all these can be done in a very short time. completed within time.

- The abrasive belt polishing machine has now become a relatively complete and self-contained new processing technology. It is favored by users because of its high processing efficiency, wide application range, strong adaptability, low cost of use, and safe and convenient operation. In foreign countries, abrasive belt grinding technology has made great progress, and its processing objects and application fields are becoming more and more extensive. It can process almost all engineering materials.